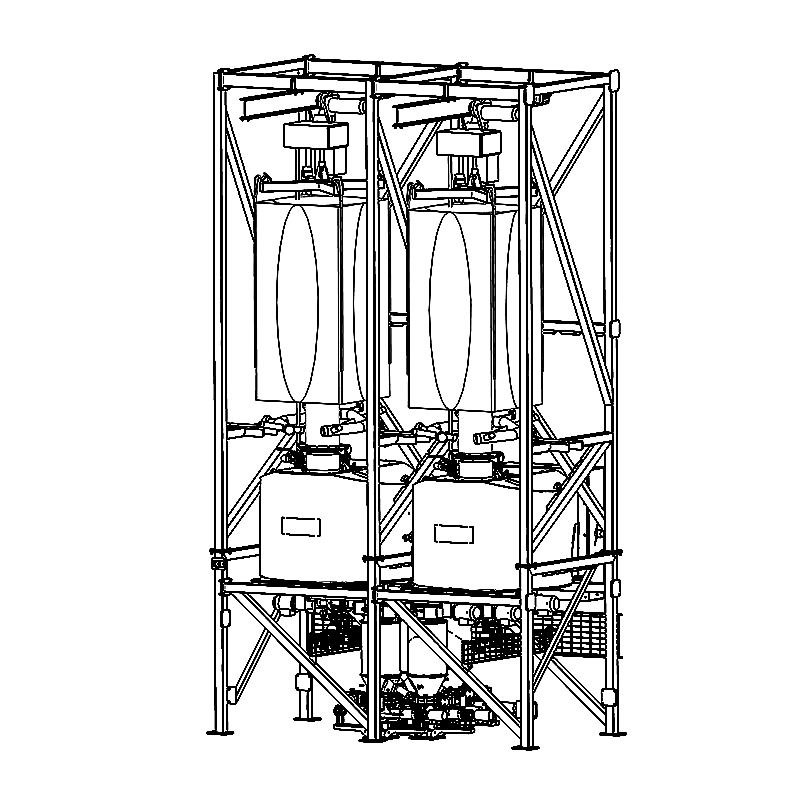

Features

- Storage and dosing of minor ingredients

Equipped with a 1,400-liter storage hopper. - 5-line principle

Our 1,400L minor component system can simultaneously dose up to five lines. - Suitable for all types of dry small ingredients

Ideal for seeds, salt, sugar, and bread improvers. - Durable and low-maintenance

Made of stainless steel and easy to clean. - High accuracy

Ensures precise dosing of minor ingredients.

Our minor component system features a 1,400-liter storage hopper for storing and automatically dosing minor ingredients. The hopper can be filled manually or via a big bag. This eliminates manual weighing, reducing human error and ensuring precise dosing.

The system can simultaneously dose minor ingredients to up to five lines. Before transport, the product is first weighed, followed by an additional control weighing at the dosing point to guarantee accuracy. This setup provides a more efficient production process and a consistent final product.