Features

- Fully Automated Filling System

The upper IBC automatically refills the lower one when a low level is detected, ensuring an uninterrupted process. - Safety

IBC skids are equipped with a drip tray to prevent liquid from reaching the floor. - Accurate Dosing

Fitted with a flowmeter and dosing system that adapts to the product’s viscosity. - Low-Maintenance Pump Solution

Hygienic pump with couplings and valves for easy installation and cleaning.

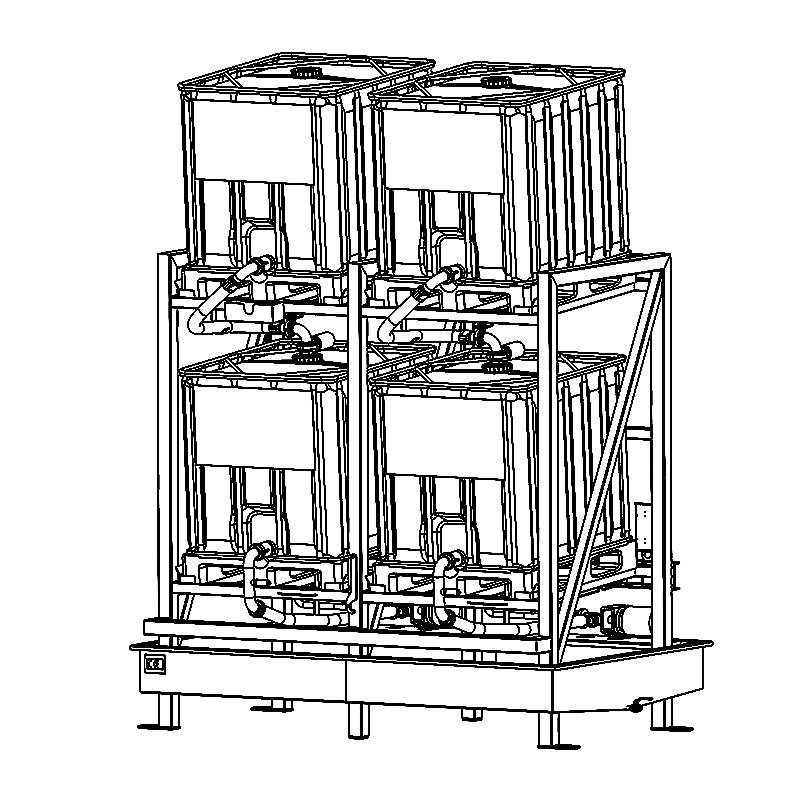

The fully automated IBC container system consists of two stacked containers. When the lower container runs empty, the upper one automatically opens its valve to refill it. With an integrated flowmeter, precise dosing to the dosing point is guaranteed, ensuring optimal control and efficiency.

The system is built within a robust stainless steel 304 frame with space for up to 12 IBC tanks (6 positions) and includes a drip tray to prevent leaks from reaching the floor. For dosing oil or fat, the system features a low-maintenance pump, valves, and stainless steel piping, all designed to handle the product’s viscosity.